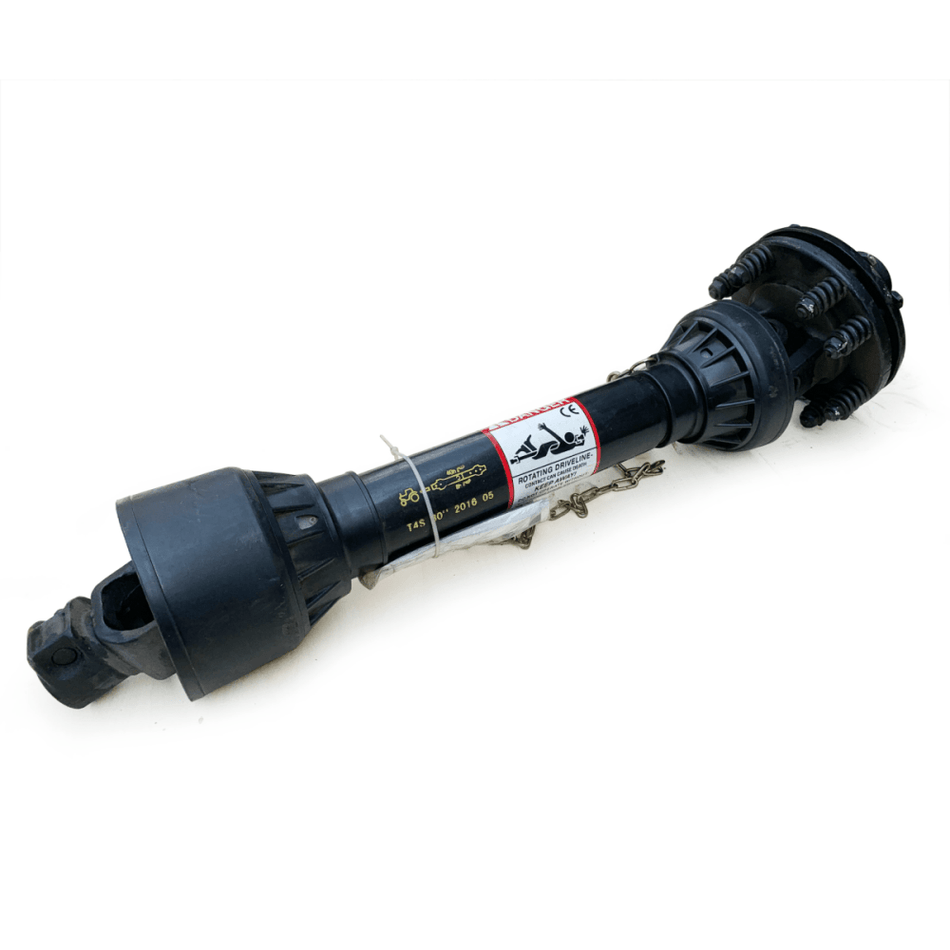

PTO driveshaft

A PTO driveshaft is the connection between your tractor and implement, transferring power with maximum efficiency. At FIMIC Implement, we understand that downtime during the planting or harvesting season is not an option.

With over a decade of experience in agricultural equipment solutions, we've helped thousands of farmers maintain productivity by offering high-quality PTO driveshafts built for durability and performance.

Our PTO driveshafts are compatible with a wide range of tractors and attachments, whether you're running a tiller, mower, rotary cutter, or baler. Precision-engineered for safety and torque transfer, these shafts come with standard and wide-angle yokes, as well as shear-pin or slip clutch options, and constant-velocity universal joints.

Every PTO driveshaft in our collection is rigorously tested to handle tough field conditions and long hours. We stock both replacement parts and complete assemblies, ensuring you can find exactly what fits your application.

If you’re looking for a reliable, field-proven PTO driveshaft that won’t let you down when it matters most, trust FIMIC Implement to deliver. We’re not just selling parts, we’re providing peace of mind for the modern farmer.